Bend Tools

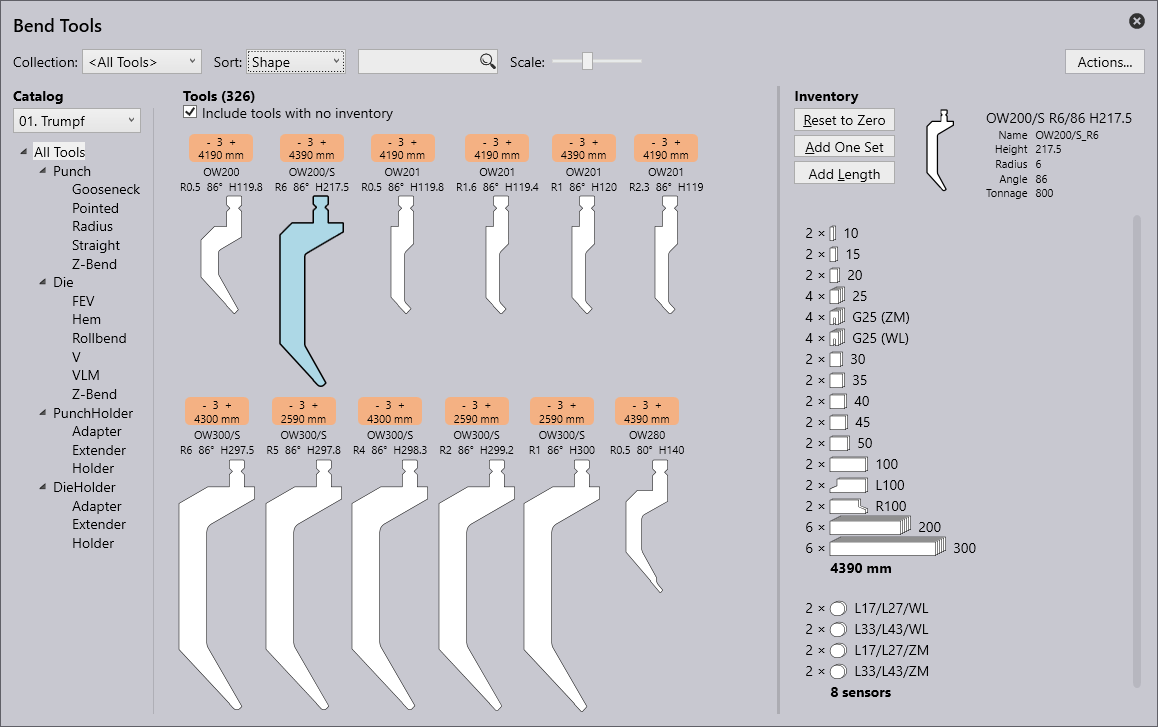

All the available tools are displayed in the inventory of tools.

New tools can also be added in bend tools.

| No | Description | Meaning |

|---|---|---|

1 |

Tool lists |

The tool lists to be worked with can be selected hereNew tool lists can be created with the option New. |

2 |

Sort |

The tools can be sorted according to specific criteria here (height, name, shape, radius, angle, die width, priority, tool management). Tools can be searched for using the search bar. Here, for example, an alphabetic search can be made for names of tools. Additionally, more complex search requests can be made. This search request finds all tools with UT or EV in the name which also meet the following conditions: angle≤30, height≥140, height≤220, radius=1. |

3 |

Scale |

The size of the view of the tools can be changed with the slide. |

4 |

Save |

Saves the tool list. |

5 |

Actions |

The following actions can be performed: - A Create tool list: A new tool list is created. - B Copy tool list: An available tool list is copied. - C Reset tool list: The number of tools in the current tool list is set to 0. - D Export tool list: The current tool list can be exported as a ".btools" file. - E Import tool list: A tool list can be imported as ".btools". - Import F ARV: A tool can be imported from an ARV fileThese tools are then custom filed in the tool catalog (this will be recreated if it was not available beforehand). - Import G DXF: A tool can be imported from a DXF file. These tools are then custom filed in the tool catalog (this will be recreated if it was not available beforehand). - Export F ARV: A selected tool can be exported as an ARV file. - Export G DXF: A selected tool can be exported as a DXF file. - Cancel H: Closes the "Actions…" window. |

6 |

Tool management |

Shows an overview of the selected tool. The following actions can be performed: - Reset to zero: The total inventory of the selected tool is removed from the current tool list. - Add a block: Adds a block of the selected tool to the current tool list. - Add tool length: Custom tool lengths can be added to the selected tool. - Add All: The complete inventory of the selected tool is loaded in the current tool list. The inventory is defined in the <All tools> tool list. |

7 |

Tool inventory |

Displays the inventory of the selected tool. Left mouse-click to add a segment and right click to remove. |

8 |

Tool without inventory |

A tool without inventory is not included in the current tool list. By clicking on the empty field a standard inventory for the tool is added and the tool is incorporated into the current tool list. |

9 |

Tool with inventory |

1 = High priority 5 = Low priority |

10 |

Tool display area |

In the tool display area, all tools from the selected tool list are displayed. Tools without inventory can also be displayed with the checkbox "Include tools without inventory". |

11 |

Tool filter |

Here, the tools of the current tool list are structured according to their type and shape. Selecting an element in this structure enables filtering. |

12 |

Catalog |

One of the many tool catalogs installed can be selected with this (including TRUMPF, custom, etc.). |

13 |

Filter condition |

The filter condition for the current tool list, which is automatically used by the auto-tooler. This can be used for a named tool list, but not for the special list <All tools>. It is possible to filter according to various aspects, including machine, material, sheet thickness, etc. |